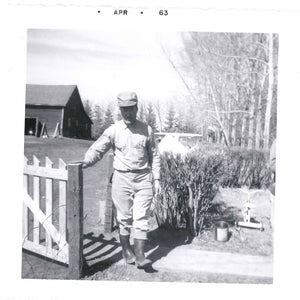

Guinness is probably the most recognizable commercial example of a Dry Irish Stout and the Hamills’ and Guinness have gone together since long before the North American craft beer boom and before Red Shed was ever even an idea. Grandpa used to always enjoy an “afternoon smash” – a Guinness in front of the tv, watching his favourite shows from his favourite chair, a well-earned treat at the end of a hard day's work.

Some of our favourite commercial examples are from local brewers Wild Winds Brewing, Sawback Brewing and Red Hart Brewing.

While Grandpa and us Hamills don’t think there is a “stout season”, we definitely see a lot of releases coinciding with St Paddy’s Day, which means you might be starting to think about brewing one now. Here is a recipe in a homebrew and commercial scale. Thanks Jen Rogers at Wild Winds Brewing for helping us out with the recipe design!

Vital Statistics:

ABV: 4.5% SRM: 30 IBU: 31 OG: 1.045 FG: 1.011

Ingredients:

|

Malt |

19L Batch |

10hL Batch |

|

Brewhouse Efficiency: 75% |

Brewhouse Efficiency: 85% |

|

|

Volume of Mash Water: 11.7L |

Volume of Mash Water: 545hL |

|

|

Amount in KG |

Amount in KG |

|

|

Parkland Pale - Red Shed (62%) |

2.44 |

110 |

|

Biscuit - Red Shed (5%) |

0.2 |

9.3 |

|

Chocolate - Red Shed (3%) |

0.125 |

5.8 |

|

Rocky Mountain Malt - Red Shed (10%) |

0.383 |

17.8 |

|

Roasted Barley - Red Shed (5%) |

0.149 |

11.6 |

|

Wheat Malt - Red Shed (15%) |

0.592 |

27.5 |

|

Hops |

Addition Time |

IBU |

19L Batch |

10hL Batch |

|

Amount in KG |

Amount in KG |

|||

|

UK East Kent Goldings |

60 Minutes |

16 |

0.02 |

1.1 |

|

UK East Kent Goldings |

15 Minutes |

15 |

0.04 |

2.1 |

Yeast: Escarpment English Ale I

Strike Water Temperature: 73°C

Water Profile: Dublin Dry Stout

Mash Rest Temperature: 64°C

Mash pH: 5.4

Brewing Process:

Mash:

- Heat strike water to 73°C.

- Add all malt and brewing salts to strike water.

- Mash in at a temperature of 64°C.

- Acidify the mash water as necessary to achieve a mash pH of 5.3–5.5.

- Hold the mash at 64°C for 60 minutes.

- Mash out by raising the temperature to 78°C for 10 minutes.

Sparge:

- Sparge the mash with water acidified to a pH between 5.2 and 5.7.

Boil:

- Bring the collected wort to a boil.

- Add bittering hops (EKG) at the beginning of the boil (60 minutes).

- Add flavor hops (EKG) at 15 minutes.

- Add Whirlfloc, and Yeastex at 10 minutes.

Cooling:

- After boiling for 60 minutes, cool the wort rapidly using a wort chiller or an ice bath.

Fermentation:

- Transfer the cooled wort to the fermenter.

- Aerate the wort by shaking or using an aeration stone.

- Pitch English Ale I yeast at a temperature of 18°C.

- Ferment at a temperature of 20°C.

- Monitor fermentation until the final gravity is consistent for 3 days.

- Once fermentation is complete, proceed to canning, bottling or kegging.

- Carb to 2.2 – 2.6 volumes of CO2